Progress on the storage silo has been on the safety cage and ladder to the top of the silo. I used 2 Tichy kits to get to the top. This is the first time I've built the Tichy kit and it was more challenging than I had expected. I attached the cage loops to the ladders first and then attached the bottom ladder to the silo by drilling small holes for a couple of very fine wire loops to secure the ladder to the side. Next the first platform was located and holes drilled for the wires to attach it. Then the second ladder and platform. The vertical straps of the safety cage (3 for each ladder) was glue to the support loops. Not an easy task and they are not straight, but there is nothing I can do about it now. I think the problem is that the cage supports are not all attached perpendicular to the ladder. Something to think about....

The last leg of ladder has yet to be installed. That will come after I attach the silo top. The top will have a railing around the perimeter.

Next to do is top railing, some exterior lighting and final assembly then primer.

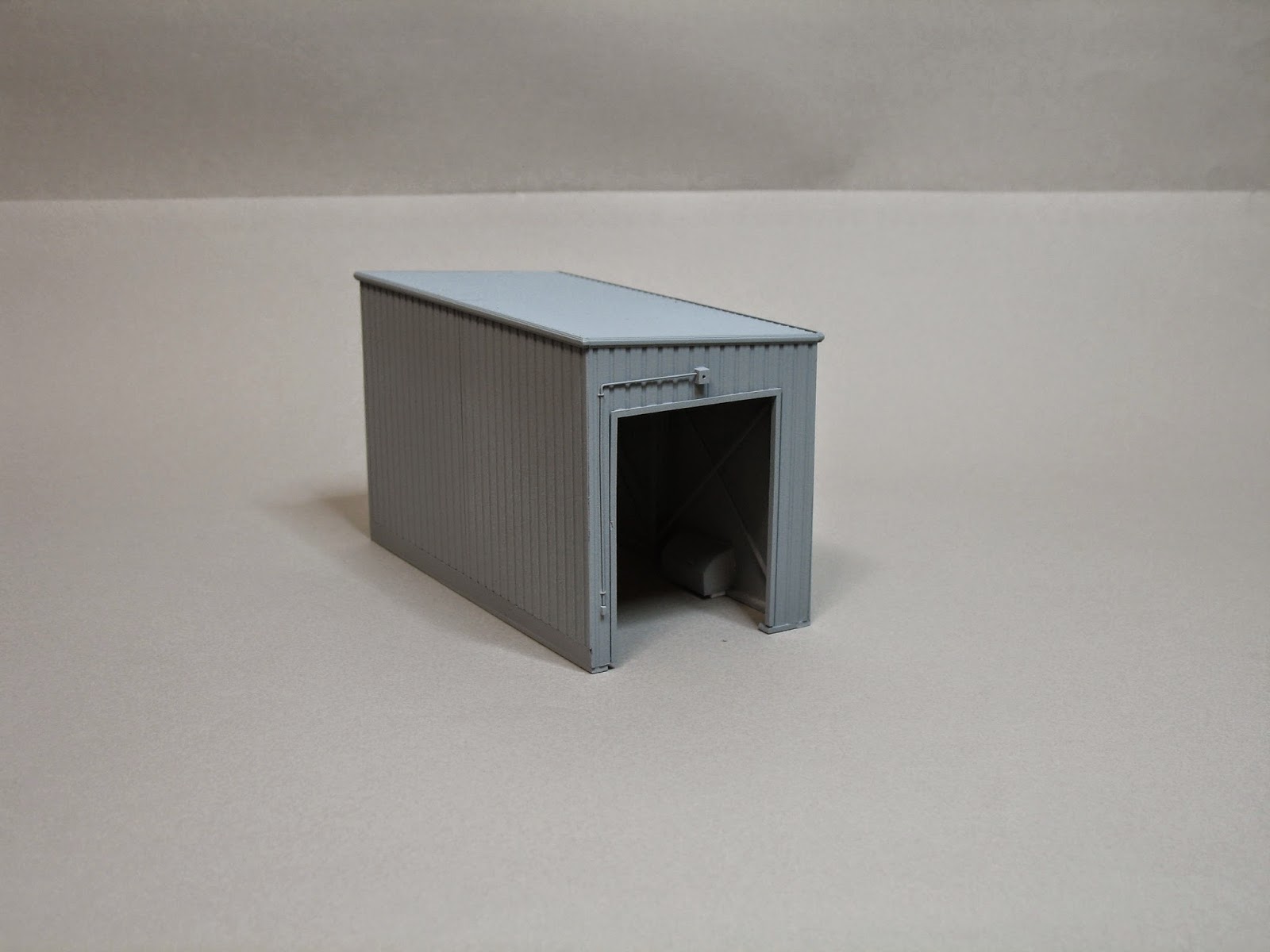

The unloading shed was painted primer grey inside and out. A non-working light fixture will be attached just above the railcar doorway.

My good friend Jeff suggested I add some bracing to the interior. I like the results, thanks Jeff!

Next for this is weathering and signage.